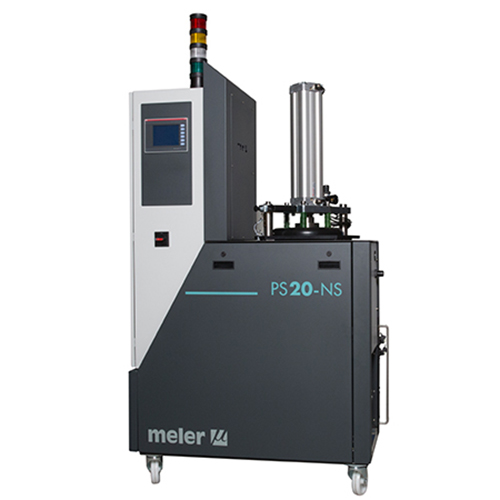

Meler PS20 Non Stop

Melter designed to melt 20 kg blocks of PUR. Controlled melting rate. Only melts the adhesive that will be used. The new block of adhesive can be inserted without stopping the unit and, therefore, the production (non-stop system).

• Significant energy savings. The functions of the melter system, hold-down cylinder and heated grille assembly are deactivated (pressure and heating) while adhesive is being consumed from the lower tank.

• Saving of adhesive. Almost no remains are left inside the bag that contains the adhesive after it has been melted.

• The single and double pump options can be used in high-accuracy automatic applications.

• The required level of adhesive is guaranteed thanks to a low-level detector in the reserve tank.

• The inside of the unit can be easily accessed thanks to its removable panels and movable electrical cabinet, which make it even easier to maintain.

• The air dryer guarantees a humidity-free protective atmosphere inside the tank, ensuring the perfect conservation of the adhesive.

MAIN APPLICATIONS Automotive industry, bookbinding, graphic arts (transparent cases), assemblies in general.