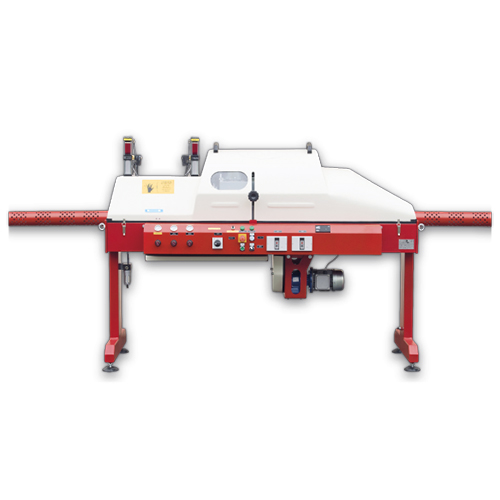

Regenerating machine for ceramic kiln rollers

The regenerating machine automatically cleans refractory rollers for ceramic kilns, removing every residue due to the baking process. The regenerated rollers recuperate their original geometrical shape ensuring the correct flow of material into the kilns.

The machine is supplied with an electronic equipment that automatize the rotation speed and the movement of the rollers in the cleaning phase. This allows to run the refractory rollers at maximum speed, that will be automatically reduced only when necessary, according to the cleaning phase.

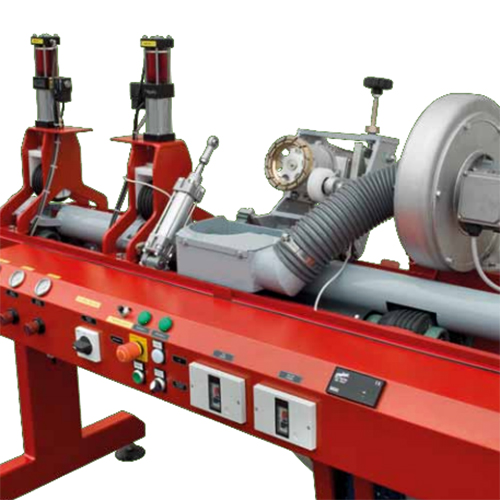

Functioning

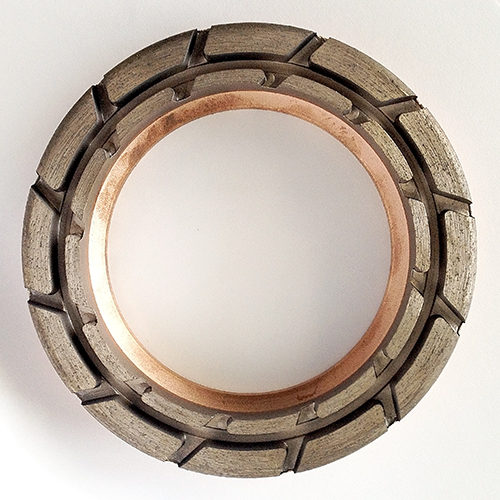

Reconditioning and cleaning of rollers through a special diamond milling cutter.

Milling cutter matching and positioning on the roller by a photocell system

Customisation

The machine is supplied with a three-phase power cable for voltage of 380V and 50Hz. These characteristics of connection to the electrical system can be modified according to specific customer’s requirements or market of destination. The machine is supplied with complete electronic equipment. Instruction for use and maintenance and information on board are available for a certain number of States and languages likewise. The machine can be supplied already properly calibrated according customer’s requirements and an automatic calibration of +/-5 mm on diameter is possible. Out of this range a recalibration of the machine is necessary according use and maintenance instructions.

Application Range

The machine can easily renew rollers of length between 1,5 up to 4 mt, with variable diameter between 27 and 60 mm